The Truth About Tagless Labels

Everything you Need to know about re-labeling your custom apparel

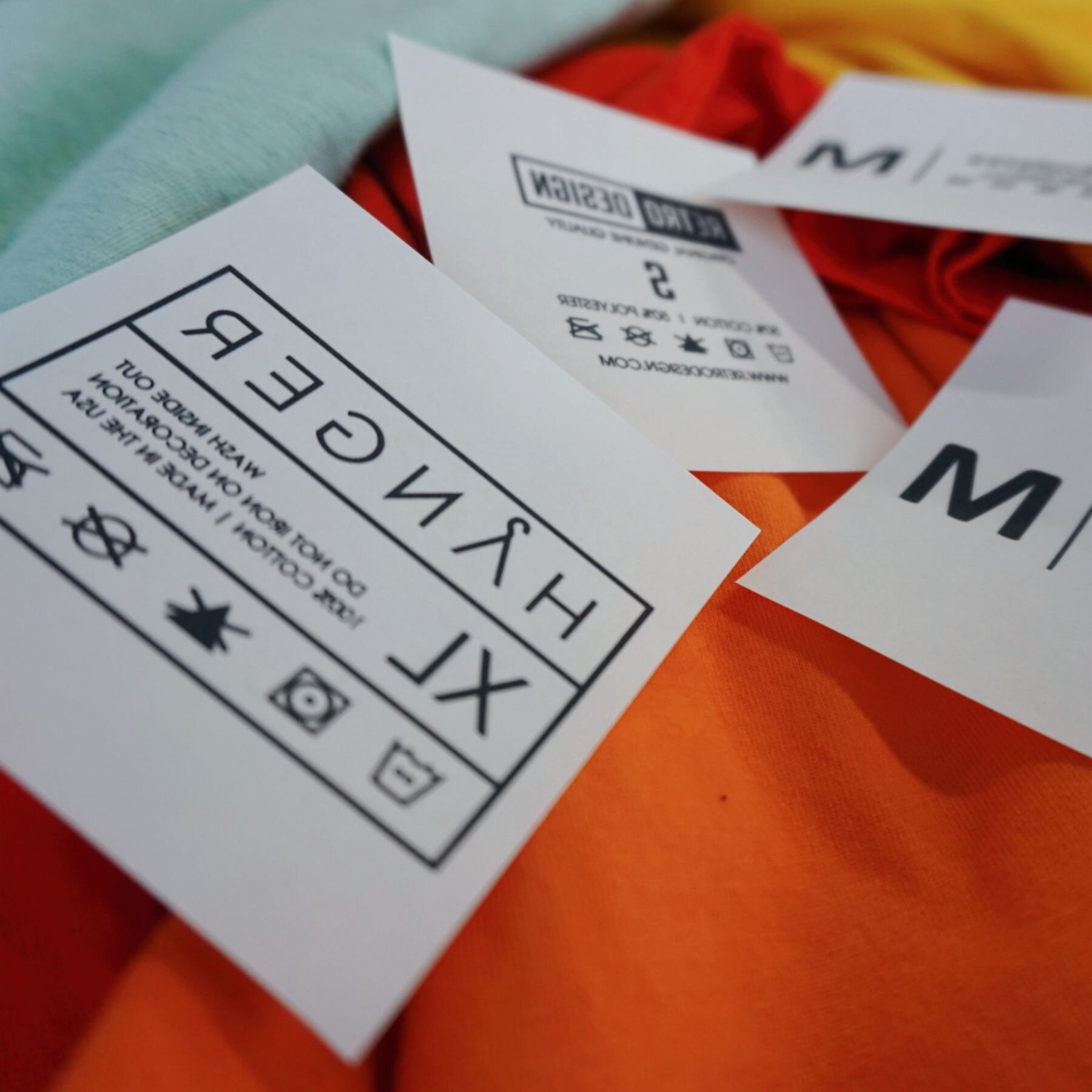

Tagless labels are an easy, cost-efficient way to increase your brand identity. From startups to industry staples, brand reinforcement is an important and effective marketing strategy. Don’t miss this opportunity to remind your customers about your amazing company and encourage repeat business.

Easily re-label your custom apparel using Endure, a custom screen printed heat transfer product designed to perform with maximum durability for tough applications like interior neck labeling.

What’s Required?

1. Fabric Content

According to the Federal Trade Commission, all textile and wool products require a label to the generic name of each fiber that equals 5% or more of the product’s weight, in order of predominance, and the percentage of the product’s weight represented by each fiber.

For example: 85% Cotton, 15% Polyester

If a product contains less than 5% of the fiber weight, it may be listed as “other fibers”, unless the fiber has significance.

For example: 96% Cotton, 4% Spandex

2. Country of Origin

This requirement is of significant importance for apparel decorators since most of the time the garments being used have been manufactured elsewhere. Products that are imported must identify the country of origin, or the country where the products were originally processed or manufactured. Products manufactured partly in the U.S. and partly abroad must identify both aspects, whereas products made entirely in the U.S. of materials also made in the U.S. must be labeled “Made in the U.S.A.”.

For example: Made in Sri Lanka. Printed in the U.S.A.

3. Identity of Manufacturer/Dealer

According to the Federal Trade Commission, textile labels must identify either the company name or the Registered Identification Number (RN) of the manufacturer, importer or another firm marketing, distributing or otherwise handling the product.

As an apparel decorator, you are re-labeling and marketing the garment as your own. Therefore, it is allowable to use your company name. In this case, the full name under which your company does business must be used.

What’s Recommended?

1. Garment Size

When applicable, feature the size of the garment on your tagless labels.

TIP: Custom screen printed heat transfers are ideal for tagless labeling. Fill up a gang sheet with labels of various sizes and use a small interchangeable platen or even a hat press to apply the transfers to the inside of the garment.

2. Care Instructions

If you plan to remove the manufacturer’s care instructions or if printing of the garment has altered the care instructions, you should be sure to include this on your tagless labels. You can provide this information either using simple text or using commonly found care instruction icons.

3. Company Logo

Include your company logo as a way to reinforce your brand identity. A strong brand identity will encourage repeat business and help build loyalty with your customer base.

TIP: Add your website or social media handle below your logo. This is a great opportunity to remind your customer how to find you!